🛠️ Air Compressor Repair: Electric Motor Troubleshooting & Fixes

Air compressors are the backbone of many industrial and commercial operations. But like any complex machinery, air compressors can fail—often at the worst possible time. Common causes include wear and tear, aging components, poor maintenance, electrical surges, and improper installation. However, one of the most frequent (and serious) points of failure is the electric motor.

🔌 Why Electric Motor Failures Matter

The electric motor is the driving force behind your air compressor. When it malfunctions, the entire system can become unreliable or completely inoperative. If you notice signs of electrical failure—such as breakers tripping, overheating, or startup issues—don’t delay. Ignoring these symptoms can lead to bigger (and more expensive) breakdowns.

⚠️ Common Causes of Air Compressor Motor Failure

1. Improper Cooling

If your motor isn’t cooling properly, it can quickly overheat. Causes include:

- Poor ventilation

- High ambient temperatures

- Dust or debris blocking cooling fans

- Extended run times under heavy loads

2. Electrical Problems

Frequent tripping, blown fuses, or dimming lights can point to:

- Worn motor capacitors

- Power surges

- Faulty wiring

- Unstable voltage supply

3. Motor Misalignment

Over time, vibration can cause misalignment. This increases friction and electrical load, leading to premature wear, overheating, and even catastrophic failure.

4. Incorrect Motor Size

If the motor is too small for the compressor, it will operate under overload conditions—leading to constant overheating and early burnout.

5. Ambient Air Temperature

Motors are typically rated for 40°C (104°F) ambient temperatures. Operating in hotter conditions without extra cooling measures will shorten motor life.

6. Incorrect Insulation Class

Choosing the wrong insulation class for your motor—especially in high-heat or high-load environments—can result in winding failures and electrical shorts. Most modern motors come with Class F insulation, but verify that this matches your site conditions.

🔧 Symptoms of Motor Trouble & Repair Tips

🔌 Compressor Trips Breakers or Blows Fuses

- Cause: Extension cords, old motor, or faulty capacitors

- Fix: Always use direct power connections. Replace old motors or damaged capacitors as needed.

💡 Lights Dim at Startup

- Cause: Worn starter capacitor

- Fix: Replace the starter capacitor to manage inrush current and avoid system-wide power dips.

⛔ Breaker Trips Immediately

- Cause: Trapped air over the pistons, often due to a faulty unloader valve

- Fix: Drain the tank and inspect/replace the unloader valve. This allows the motor to start without pressure resistance.

⚙️ Motor Repair vs. Replacement: What to Consider

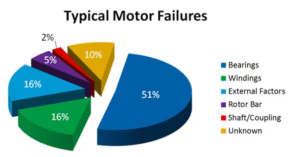

Not all electric motor issues require a full replacement. But ignoring small problems can turn into expensive downtime later. Look out for:

- Worn bearings

- Shorted windings

- Burnt or corroded wiring

- Unusual noise or vibration

📈 Why Proper Maintenance Matters

Regular servicing and preventive maintenance help ensure your air compressor operates at peak performance. Keeping the electric motor in top condition reduces breakdowns, improves energy efficiency, and extends the life of the entire system.

Whether you’re a facility manager, plant technician, or service contractor, a strong understanding of electric motor repair is essential for minimizing downtime and protecting your investment.

🔍 Final Thoughts

Whatever the issue—be it overheating, startup failures, or blown fuses—most compressor motor problems can be solved with the right troubleshooting approach. But for persistent or complex issues, always consult a qualified technician.

ElectricalMechanicalJobs.com is your go-to platform for hiring and finding skilled professionals in:

- 🧰 Air Compressor Technician Jobs

- ⚡ Electric Motor Technician Jobs

- 🔧 Equipment Mechanic Service & Repair Roles

📢 Are You Hiring or Looking for Work?

Post your job or find your next opportunity at ElectricMotorShopJobs.com – where industry meets expertise.

Keywords: air compressor technician jobs, electric motor technician jobs, air compressor service technician jobs, Air Compressor Electric Motor Repair, electric motor shop jobs