Air Compressor Electric Motor Repair

Air compressors can fail from an assortment of different reasons: Normal wear and tear, lifespan and age of the unit, poor maintenance, power surge, install issues are just a few the come to mind. Apart from these failures, one of the major failures occurs in Electric Motors’ of the air compressor which is the main part of this.

If you notice an electrical issue, you need to take a look at it or have a professional come out as soon as possible. It could be anything from your motor capacitors to misfiring piston rings which can lead any one of problem mentioned below:

If you notice an electrical issue, you need to take a look at it or have a professional come out as soon as possible. It could be anything from your motor capacitors to misfiring piston rings which can lead any one of problem mentioned below:

Improper Cooling

A few normal reasons for a compressor’s motor overheating are inappropriate ventilation, high surrounding air temperature, low pull pressure, and unreasonable mileage. Assuming any of these elements keep the engine from cooling down properly, it will turn out to be progressively more smoking over the long run.

Electrical Problems

A couple of ordinary explanations behind a compressor’s motor overheating are improper ventilation, high encompassing air temperature, low draw pressure, and absurd mileage.

Misalignment

All motors produce vibrations as they operate; however, motor misalignment can create excessive vibrations and cause friction between components. The friction of components will begin to wear down and place extra load on the motor, which will cause the motor to draw excessive current and overheat.

Incorrect Motor Size

When considering the size of the motor, it is important to account for the site conditions and the size of your air compressor. A motor that is too small will operate in an overload condition, and the motor will overheat.

Ambient Air Temperature

Motors rely on circulated air for the proper cooling of the motor windings and bearings. Motors have a rated ambient air temperature of 40°C (104°F). If the motor is located in an area where the surrounding air temperature is greater than 40°C (104°F), the motor will experience higher operating temperatures.

Incorrect Insulation Class

While taking a gander at which insulation class to pick, it is basic to choose the one that is appropriate for your compressor’s motor alongside site conditions. Neglecting to do as such can bring about overheating and an abbreviated future for the engine. The motor winding insulation, which safeguards the conductive wires folded over the stator, can separate at temperatures past their most extreme cutoff. A weakened point in the protection will bring about an electrical shy of the windings. Knowing the temperature rise within your motor, along with the ambient temperature of your plant, will allow you to determine which insulation class is best. Most motors are equipped with Class F insulation.

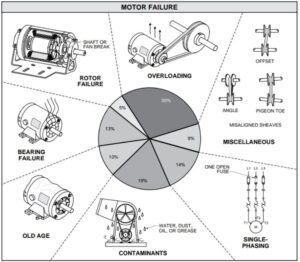

While the major percentage of Electric motor failures can be seen below Pie chart, which consist of stator/Windings, Bearings, External factors and unknown reasons.

Different Electric Motor failures of Air compressor

Below are the major reasons, which should be considered for repairing the Electric motor of Air compressor:

- Compressor Blows Fuses and Breakers

Assuming that your compressor is plugged into a working outlet and powered on, the following issues could be causing fuses to blow:

- Extension cords: If your compressor is connected to an outlet via an extension cord, the motor could be deprived of sufficient energy, causing the motor to overheat. Compressors are not like home electronics, which can suffice on extension cords and power bars. An air compressor should only be powered through a direct connection to a power source.

- An old motor: If your compressor has run on the same motor for many years, it could be time for a change-out. An older motor is liable to have worn windings, loose capacitor wires and other general wear that could easily result in blown fuses and breakers.

If the tank seems to lug at times of high pressurization, there is probably an issue with the motor capacitor.

- Dimmed Compressor Lights at Startup

An air compressor consumes massive volumes of power at the time of startup. This is known as the inrush, which vastly exceeds the amount of power generally consumed throughout the rest of a usage cycle. To prevent fuses from breaking during this inrush, compressor motors are equipped with starter capacitors, which manage the incoming power. A dimming light is one of the tell-tale signs that the starter capacitor is worn and due for a replacement.

- Breaker Trips at Startup

If your air compressor trips off the moment it powers on, the issue is likely caused by trapped air over the pistons. To test for this problem, shut off the tank, unplug it from the power supply and drain the tank of all air. This should relieve the pistons of undue air pressure and allow the tank to start without further issues. Trapped air over the pistons is usually caused by a faulty unloader valve, which should be inspected, cleaned and possibly replaced if the issue persists.

Electric motor plays the vital role for working of Air compressor. To keep Air compressor in proper working all these procedures of repairs and maintenance of Electric Motor should be ensured to have a safe working of all parts. In order to keep compressors operating at peak performance, maintenance of its specific components is key. Not to mention, proper maintenance keeps parts running safely and reliably, helping to reduce operating costs and improve efficiency.

Whatever the cause of the problem, the symptoms can be frustrating, costly and time-consuming. Most such problems can be corrected with proper air compressor troubleshooting. As a compressor accumulates hours, problems will invariably become more frequent, and possibly also more difficult and time-consuming to repair.

ElectricmotorShopJobs.com keywords: air compressor technician jobs, electric motor technician jobs, air compressor service technician jobs, Air Compressor Electric Motor Repair. electric motor shop jobs