An electric scooter motor provides an advantage of relatively lower maintenance cost thus easy to maintain.

ELECTRIC SCOOTER MOTOR REPAIR

An electric scooter motor provides an advantage of relatively lower maintenance cost thus easy to maintain. This is because such a motor has a lesser number of parts hence not very prone to breakdown Lack of a proper care and maintenance may lead to breakdown of the motors and in such a case a repair maybe be done to restore its functionality and to continue servicing the operation with little or no interruption. Therefore, to minimize and alleviate all this issues, proper care and maintenance is inevitable to protect the motors from the risks of breakdown and damages.

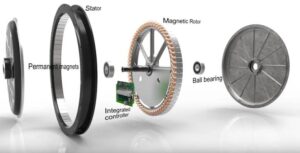

The motor is a significant part of the electric scooter and is used to run the electric scooter. The motor also powers the electric scooter. The hub motor can be either geared or brushed. The configuration is such that the motor is connected to the rear wheel or front wheel of an electric scooter as shown below; –

Figure 1; -Configuration of a motor and electric scooter motor

The figure below shows the rotor of the motor. The rotor is the one which rotates hence runs the electric scooter; –

Figure 2;-The rotor of the motor that runs the electric scooter

As a result, any damages subjected to the motor renders the electric scooter functionless and less efficient. An electric scooter has parts and components which are prone to damages related to over voltages, overuse or even stress and strain during riding. As much as preventing any risks is significant, a breakdown as a result of damage or wearing out of a few parts or components., the motor can be easily diagnosed and repaired

Being well versed with the roles and positioning of the motor instills in us with an idea on how to detect where problems or faults are in case of a breakdown occurs. In the event that a breakdown occurs, the following strategies can be employed to clear the fault or repair the motor;

1.CHECKING THE CONDITION OF THE WIRES

The faults of overload or overvoltage may heat, burn or melt the wires or the components of the electric scooter. Therefore, in the event of checking their conditions, if a smell of burnt plastic or rubber is detected, that’s an enough indication or inference that either the wires or components have been overheated. Due to overheating, the heat can melt the electromagnetic wire winding off the plastic insulation This causes motor failure thus the motor will not run thus rendering it impossible to run the electric scooter. The repair strategy or remedy to this is to replace the heated, burnt or melted wires or components so as to restore the functionality of the motor hence the electric scooter. If the motor is damaged or affected to a larger extent, the motor can be replaced immediately.

2.CHECKING THE CONTROLLER BOARD OR THE HALL SENSORS

In the event that the control boards or hall sensors comes into contact with water this may damage them as they are passive circuits hence water resist therefore causing failure in the whole system. The hall sensors can also be damaged by heat, vibration or can be of poor quality thus affecting their functionality. The repair strategy or remedy to this is to replace the faulty controller board or hall sensors with a functional board or hall sensors that will restore the functionality of the electric scooter.

3.CHECKING THE CONDITION OF THE MOTOR BEARINGS

In the event of checking the condition of motor bearings and it’s found out that the motor bearings no longer roll smoothly as compared to their initial state or if the misalignment of bearings has taken place, then that’s a clear indication or an inference that there is a problem with the bearings which hinders or slows down the operation or functionality of the motor hence the functionality of the electric scooter in general. This can be rectified by oiling or greasing the bearings to reduce friction hence permit the smooth rolling of the bearings on their grooves. In case of a misalignment, the bearings can be aligned properly on their grooves so that they can roll freely without any distraction or opposition to their movement thus making it easier for them to transfer the loads from the shaft to the motor. This restores the functionality of the motor hence the electric scooter.

4.INPSECTION FOR LOOSE WIRES AND CONNECTORS

The wires might not be heated, melted or burnt but their connections can be loose or not very tight as required. In the event that a wire comes off easily or is not secure when gently tugged, then that is a clear indication that the wire is loose or not tight as required. A loose wire may create an open circuit thus preventing the flow of current in a circuit that it is connected to. This causes motor failure hence the failure of the electric scooter. The remedy of this failure is to secure the loose wires tightly to eliminate the looseness. This ensures that the current flows as expected thus restoring the functionality of the motor hence the electric scooter.

5.CHECKING THE CONDITION OF THE BATTERY (POWER SUPPLY) OR THE CHARGER

The function of the battery or the power supply is to deliver power to the moto hence switch the motor in a functionality mode. A damaged battery means that no power is delivered to the motor thus the motor is rendered functionless since the motor stops running.

Also, the battery might be in good condition but the charger faulty. A faulty charger will not be able to charge the battery however good the battery is. No power is stored in the battery thus the battery will not be able to power the motor. As a result, motor also will not be able to run the electric scooter.

Such failures can be alleviated by replacing the bad battery with a good one or buying a charger that is good so as to be able to power the battery hence power the motor and to restore the functionality of the electric scooter.

6.TESTING THE CONDITIONOF THE BRAKE LEVER

The role of the brake lever is to inform the speed controller to evaluate when to stop in the event that the brakes are applied. In the event that the brake lever becomes damaged or is subjected to wear and tear, the brake lever locks the electric scooter in such a way that it hinders the running of motors and wheels.

To detect whether there is a problem with the brake level, the access to the controller is permitted by opening the electric scooter. The brake lever is then disconnected from the controller. The brake lever is replacing in the event that the electric scooter is the one running. Otherwise, that’s a clear indication that the brake level has no any problem and is therefore function the right way.

The electric scooter can also be taken to a mechanic for more inspection or testing and also the motor can be replaced to rectify the problem.

7.INSPECTION OF THE MOTOR

The motor hardly breaks down or malfunction, but in some cases his happens. One of the most popular causes of motor failure is humidity. Humidity refers to the quantity of moisture in the atmosphere. Moisture may find its way into the motor thus causing it to stop functioning. This renders the motor incapable of driving the electric scooter.

To rectify this, the motor can be replaced in the event that there are visible signs of damages caused by moisture. Also the motor can be installed in dry places to avoid moisture from gaining access into the motors.

8.TAKING THE ELECTRIC SCOOTER TO MECHANIC

In the event that the electric scooter motor is not working or if there are uncertainties on which wires and components to be tweaked, the electric scooter motor can be taken to a local repair shop or to the related related so that it can be checked for the likely causes of failure. To get the best services, it’s advisable that the electric scooter motor be taken to a professional who will address the issue in ana elegant and practical fashion and also to prevent more damages.

9.CHECKING THE POWER TRANSMISSION SYSTEM

An electric scooter employs a single-speed transmission hence more efficient to accelerate the electric scooter in comparison with fuel engines. In the event that the electric scooter runs but remains in a stationary position, the problem could be in the power transmission system of the electric scooter. T be issue could be missing parts or failure to function in the desired way. The possible causes of such issues could be the wear and tear of the rear wheel freewheel clutch, or either a missing or damaged chain sprocket, chain, cog or belt.

To rectify all this issues, the parts can be inspected for any damages or problems thus narrowing down the escape.

10.INSTALLING THE ELECTRIC SCOOTER CHAIN OR BELT PROPERLY

The motor employs two types of drive systems in its operation. Namely; -the belt drive or chain drive. The difference between the two is that a belt drive uses a belt rather than a chain in its operation. On the other hand, a chain drive contains pinion and sprocket gears as well as the chain. Some electric scooter motors have a direct link between the drive pinion and the engine.

It’s therefore advisable to periodically check the belt or chain so as to make sure that they are installed the right way on the gears. The electric scooter is then tested so as to establish whether its wheels are turning.

11.CHECKING THE CONDITION OF THE REAR FREEWHEEL CLUTCH

In the event that the motor and belt or chain drive runs but the rear wheel remains in a stationary position, that’s a clear indication that the rear wheel freewheel clutch has some issues or is defective. To narrow down the cause, it is taken to a mechanic for more inspection and if it is defective, it is fixed or replaced with a functional one.

12.CHECKING THE CONDITIONS OF THE BELT, CHAIN, COG OR SPROCKET

In the event that the motor runs but the belt, chain or real wheel are not spinning, the possible likely cause could be that either the belt or chain fell off, the belt has no sufficient tension or there might be a damaged, loose or missing sprocket or cog. To narrow down the escape, these parts should be checked and if there are some issues, the parts can be replaced or services so as to restore their functionality.

13.TAKING THE ELECTRIC SCOOTER TO A MECHANIC

If the strategies mentioned above are not fruitful, the electric scooter can be taken to a professional or local mechanic for further inspection so as to alleviate the issues. A professional will help to solve the problem in an elegant and practical fashion and will also ensure that there is no further damages.

14.INSPECTING THE CIRCUIT BREAKER OR FUSE

In instances whereby the electric scooter uses a circuit or fuse, it is advisable to check the conditions of the circuit breaker or fuse. Fuses can melt or burn out in case of the faults of an overcurrent or overvoltage. Also the condition of the circuit breaker can be checked. A multi-meter is used to establish whether the circuit breakers or fuses are working or not. Burnt or melted fuses can be replaced. Fault circuit breakers can be replaced or if the circuit breaker is in a good condition it can be mechanically reset.

15.INSPECTION OF THE SPEED CONTROLLER

It is inferred that the speed controller is defective if and only if all the electrical components around it are functional but the electric scooter is functionless. Signs of a defective speed controller includes smell of burnt plastic or rubber or any damaged wire connectors or wires. To narrow down the escape, the defective speed controller can be replaced with a functional speed controller. The damaged wires or wire connectors can be replaced with healthy wires which are functional.

CONCLUSION

From the foregoing, it can be inferred that the electric scooter motor is a component which is very prone to damage. Lack of proper care and maintenance can render the parts and components functionless. It can also burn or melt them.

In case of a breakdown, the described straggles can be employed in the process of repairing the electric scooter motor so as to restore their functionality. These strategies alongside proper care and maintenance will ensure that our electric scooter motors have a longer life span and can give us a very good service.

REFERENCES

- Electric scooter manuals.

- https://www.mearth.com.au/blogs/news/how-to-fix-an-electric-scooter-motor

- https://www.electricscooterslondon.chttps://www.mearth.com.au/blogs/news/how-to-fix-an-electric-scooter-motor

ElectricmotorshopJobs.com keywords: scooter repair jobs, ev motor jobs, scooter electric motor jobs, electric scooter repair jobs, electric scooter technician jobs, Electric scooter motor repair basics