Electric motors are the backbone of modern industry, powering everything from manufacturing equipment and home appliances to automation systems and electric vehicles. Behind their smooth and efficient performance lies a critical internal component: the winding. Among the many winding techniques used in motor construction, random winding stands out for its versatility, cost-effectiveness, and wide-ranging industrial adoption. In this guide, we explore what random winding is, how it works, why manufacturers prefer it for certain motor types, and—most importantly—the real-world industries where it truly shines. This article also highlights the role of materials, production efficiency, and emerging technologies reshaping the method today.

What Is Random Winding?

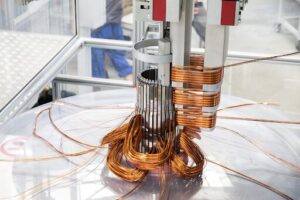

Random winding, also known as “jumble winding,” is a coil-forming method in which magnet wire is wound around a stator slot in a naturally overlapping and non-layered pattern. Unlike precision winding—which arranges each turn in an orderly layered form—random winding relies on high-speed automated winding machines to lay the coils rapidly and without strict geometric alignment.

This does not mean the winding is unpredictable or poorly constructed. Instead, random winding is engineered to distribute wire turns efficiently while minimizing resistance, maintaining coil integrity, and reducing production time. The slight randomness in the arrangement allows for dense packing of wire within the stator slots, delivering excellent electromagnetic performance at a lower cost.

How Random Winding Works

Random winding is performed using automated needle-winding machines, which rotate wire at high speed into stator slots. These machines precisely control wire tension, number of turns, and overall filling factor. The process usually includes:

1. Wire Feeding and Guiding

Specialized feeders supply enamel-coated copper or aluminum wire into the machine, ensuring constant tension.

2. High-Speed Needle Insertion

A programmable needle inserts wire into the slots as the stator rotates. The overlapping pattern forms naturally as the machine lays each turn.

3. Slot Insulation

Before winding, the stator slots are fitted with insulating paper or polymer sleeves to protect the enamel coating from abrasion.

4. Coil Shaping and Finalizing

After winding, coils are pressed and shaped to fit compactly within the stator footprint. Some designs require epoxy impregnation to improve structural stability.

This automated method makes random winding suitable for mass production, offering high throughput without compromising electrical performance.

Advantages of Random Winding

Random winding technology has been adopted widely because it brings several engineering and commercial benefits:

✔ Faster Production

Its automated nature enables high-volume output, ideal for industries needing millions of motor units per year.

✔ Lower Manufacturing Cost

Random winding requires less complex machinery compared to precision winding, lowering overall production costs.

✔ Excellent for Small and Medium Motors

It provides high slot fill factors suitable for compact motors such as those used in household appliances and fans.

✔ Durable and Reliable

Epoxy filling and insulation make random-wound motors resilient against vibrations and heat—important for motors operating for long hours.

Performance Considerations

While random winding is efficient and affordable, engineers must consider certain performance factors:

- Slightly higher copper losses compared to precision winding

- Variation in heat distribution due to irregular wire placement

- Potential noise levels in certain motor types

- Limited suitability for ultra-high-performance applications such as aerospace or premium EV motors

Despite these limitations, technological improvements in insulation systems, automated machines, and wire coatings continue to enhance the reliability and efficiency of random-wound motors.

Real-World Applications of Random Winding

Random winding has become a standard method in multiple industries because of its balance between performance, cost, and manufacturability. Here are the top sectors where it is most commonly used:

1. Household Appliances

Home products rely heavily on small, dependable electric motors, including:

- Washing machines

- Air conditioners

- Vacuum cleaners

- Refrigerators

- Microwave fan motors

Random winding ensures these appliances remain affordable without compromising reliability.

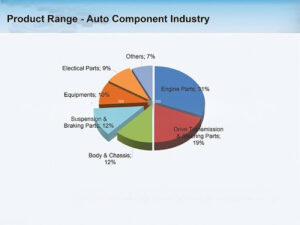

2. Automotive Components

Numerous auxiliary systems in modern vehicles use random-wound motors:

- Cooling fans

- Windshield wipers

- Fuel pumps

- HVAC blowers

Their compact design and durability make them ideal for automotive environments.

3. Industrial Machinery

In factories, random-wound motors appear in:

- Conveyor belts

- Pumps

- Industrial fans

- Packaging machines

Manufacturers favor them for their long operational life and maintainability.

4. HVAC and Ventilation Systems

From residential fans to commercial ventilation units, random-wound motors provide high efficiency with low energy consumption.

5. Office and Commercial Devices

Items like printers, scanners, shredders, and vending machines rely on random-wound motors for lightweight operation.

Future Trends in Random Winding Technology

Innovation is pushing this winding technique forward even further. Among the newest advancements:

AI-Controlled Winding Machines

Artificial intelligence is helping machines detect winding inconsistencies in real time, improving quality control.

Thermal-Resistant Insulation Materials

New enamel coatings and slot insulations allow random-wound motors to operate at higher temperatures, increasing lifespan.

Miniaturization for Smart Devices

Compact random-wound micro-motors are now being designed for smart home gadgets, robotics, and IoT applications.

Green Manufacturing

Eco-friendly materials and energy-efficient production systems make random winding more sustainable than ever.

Conclusion

Random winding has become one of the most essential techniques in electric motor manufacturing, offering a smart balance between performance, durability, and cost. Its wide use across industries—household appliances, automotive components, HVAC systems, and industrial machinery—proves its long-term value. As new insulation materials, AI-powered manufacturing, and energy-efficient systems emerge, random winding continues to evolve, ensuring electric motors remain reliable workhorses of modern technology.